Understanding Environmental Cable Standards

Environmental regulations like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) were established to protect human health and the environment from harmful substances in electrical and electronic equipment.

For network infrastructure products—such as Ethernet cables, patch cords, and fiber optic cables—compliance with these standards is no longer optional but essential for global market access.

What RoHS and REACH Mean for Cable Manufacturing

RoHS limits the use of six major hazardous materials, including lead (Pb), cadmium (Cd), and mercury (Hg), while REACH requires manufacturers to disclose and register all chemicals used in production.

For cabling products, this impacts:

-

Copper conductor purity: ensuring no lead or cadmium contamination.

-

Insulation and jacket materials: shifting to halogen-free compounds like LSZH for safer burning.

-

Manufacturing process: adopting eco-friendly extrusion and surface treatment processes.

Manufacturing & Testing: From Process to Certification

To achieve full REACH and RoHS compliance, cable manufacturers need to establish strict quality control from material sourcing to final inspection.This includes:

-

Tracking raw material origins and maintaining supplier compliance documentation.

-

Enforcing clean production processes to eliminate chemical cross-contamination risks.

-

Conducting regular testing and verification, such as XRF scans and laboratory chemical analyses, followed by third-party certifications like CE, UL, or ETL to confirm conformity.

Benefits of Eco-Compliant Cable Design

Environmental compliance doesn’t only meet legal requirements—it also improves performance.

-

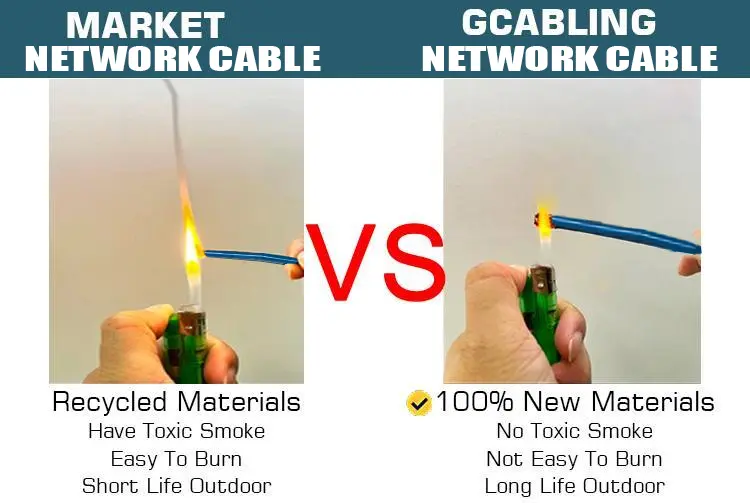

Enhanced safety: non-toxic, low-smoke emissions protect people and equipment.

-

Long-term reliability: eco-friendly materials are more resistant to oxidation and aging.

-

Market access: products meeting RoHS/REACH can be exported globally without restriction.

-

Corporate responsibility: aligns with global ESG (Environmental, Social, and Governance) trends.

Conclusion

Environmental regulations like REACH and RoHS are shaping the future of structured cabling.

By adopting compliant materials and advanced production techniques, Gcabling delivers cables that protect both your network and the planet.

For businesses seeking sustainable, globally compliant network infrastructure—Gcabling provide the trusted last-mile connectivity solution.

How Gcabling Ensures Compliance

At Gcabling, every cable—from Ethernet Patch Cables to fiber optical patch cords—is designed under ISO and IEC standards, with RoHS/REACH certified raw materials and process control.

Each batch undergoes:

-

Material traceability verification

-

Independent third-party certification (UL, CE, ETL)

-

Routine in-house compliance testing for restricted substances

This commitment ensures our customers receive safe, sustainable, and high-performance cabling solutions for long-term network reliability.