Fiber optic networks support modern data centers, FTTx deployments, enterprise LANs, and cloud infrastructure. While fiber optics deliver high bandwidth and long transmission distances, their performance is highly dependent on proper physical installation. One of the most critical — and often underestimated — parameters is the fiber optic bend radius.

Ignoring the minimum bend radius for fiber optic cable can result in signal loss, increased attenuation, and long-term reliability issues. This article provides a practical, installation-focused guide to fiber bend radius, including definitions, standards, common mistakes, and best practices.

What Is Fiber Optic Bend Radius?

The fiber optic bend radius refers to the smallest radius a fiber cable can be bent without causing unacceptable signal degradation or physical damage. It is measured from the inside of the bend, not the outer curve.

Fiber optic cables transmit data through light propagation within a glass core. When the bend radius is too tight, light escapes the core, leading to fiber cable bending loss. Over time, excessive bending can also cause microscopic cracks in the fiber, reducing long-term performance.

Manufacturers specify two bend radius values:

-

Dynamic bend radius – during installation or pulling

-

Static bend radius – after the cable is installed and fixed

Respecting both values is essential for reliable fiber optic installation.

Why Fiber Bend Radius Is Critical to Network Performance

Signal Loss and Attenuation

Exceeding the minimum bend radius for fiber optic cable causes two major problems:

-

Macrobending: Visible tight bends that allow light to leak out of the fiber core

-

Microbending: Small, invisible deformations that distort the fiber geometry

Both macrobending and microbending increase attenuation, especially in high-speed links such as 40G, 100G, and 400G Ethernet.

Long-Term Fiber Reliability

A fiber link may initially pass certification tests even if bend radius rules are violated. Proper fiber bend radius control significantly extends cable service life.However, repeated stress often leads to:

-

Gradual signal degradation

-

Intermittent link failures

-

Higher maintenance costs

Standards Compliance and Warranty Protection

Most fiber optic manufacturers and international standards (ISO/IEC, TIA) clearly define bend radius limits. Failure to comply may:

-

Void product warranties

-

Cause acceptance test failures

-

Increase operational risk in enterprise

Minimum Bend Radius for Fiber Optic Cables

Although exact values depend on cable construction, industry best practices follow these general rules:

During Installation (Dynamic Bend Radius)

-

Minimum bend radius: 20 × cable outer diameter

This applies while pulling, routing, or repositioning fiber cables under tension.

After Installation (Static Bend Radius)

-

Minimum bend radius: 10 × cable outer diameter

Once installed, fiber cables must maintain this bend radius permanently, including inside racks, patch panels, and enclosures.

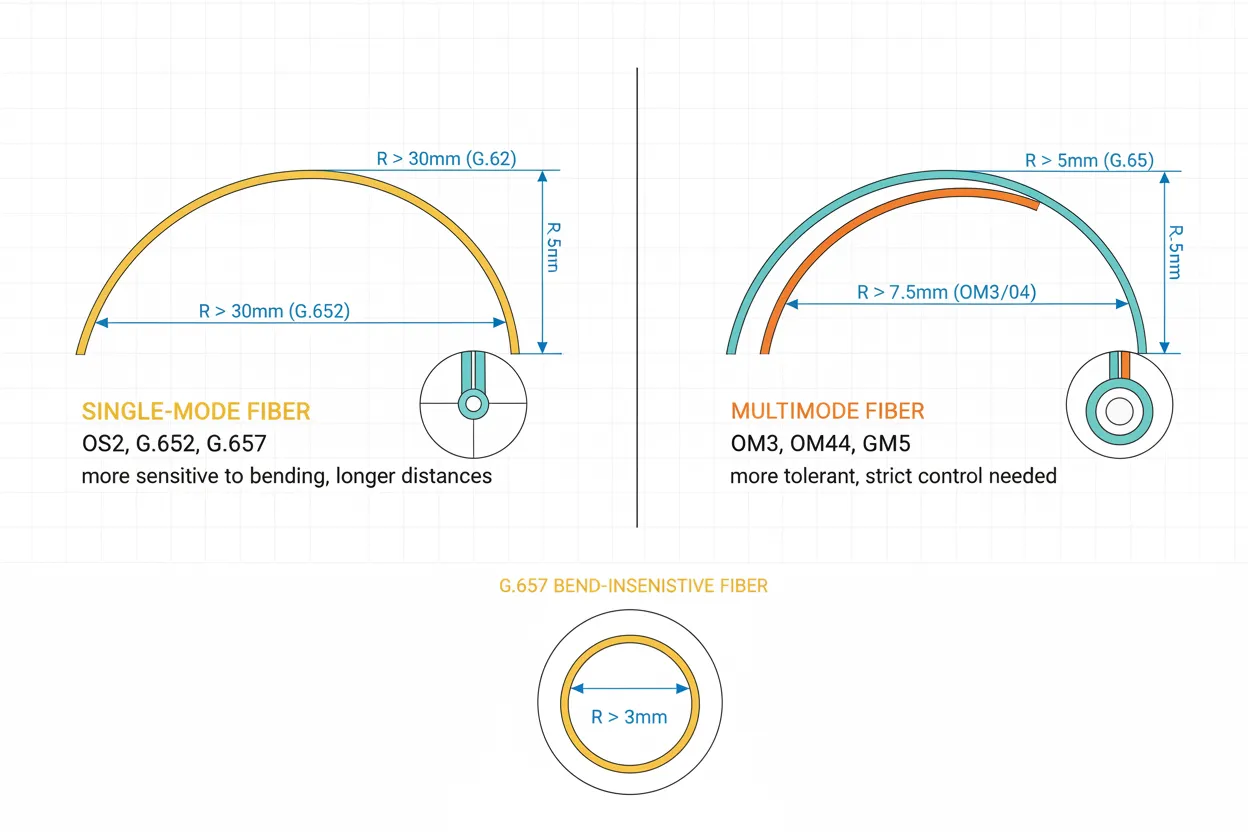

Bend Radius for Single Mode vs Multimode Fiber

-

Single-mode fiber (OS2, G.652, G.657): More sensitive to bending but supports longer distances

-

Multimode fiber (OM3, OM4, OM5): Slightly more tolerant but still requires strict bend control

Bend-insensitive fiber (G.657) allows tighter bends but is not immune to damage.

Common Fiber Bend Radius Issues and Solutions

Improper fiber bend radius control is a major cause of optical signal loss, typically resulting from tight routing in racks, overfilled cable trays, excessive pulling tension, or ignoring manufacturer bend radius specifications. These practices can lead to macrobending and microbending, increasing attenuation and reducing long-term link reliability. Effective prevention requires proper route planning, use of fiber management accessories such as bend radius limiters and organized patch panels, and mandatory post-installation testing (insertion loss and OTDR) to verify compliance and ensure stable network performance.

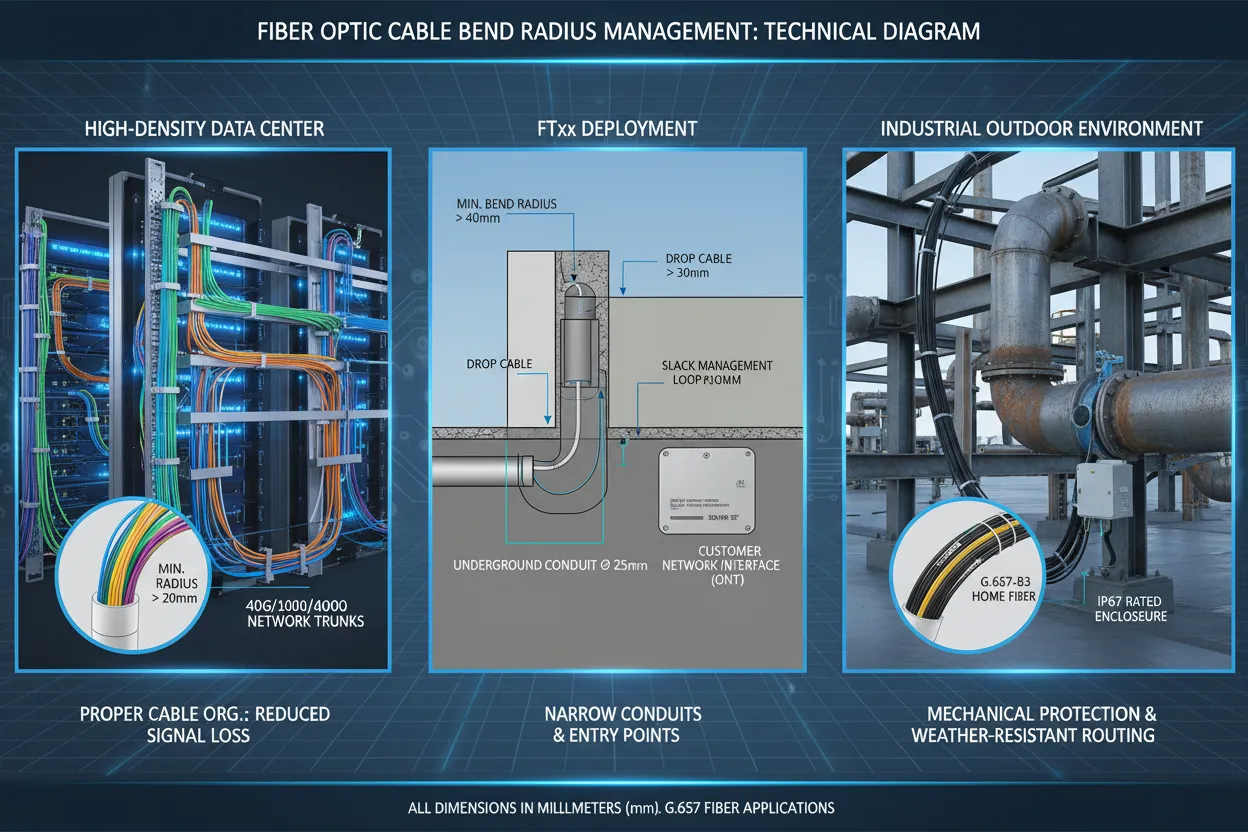

Bend Radius in Different Application Scenarios

Bend radius management becomes increasingly critical in high-density data centers supporting 40G/100G/400G networks, where tight spaces and frequent reconfiguration are common, as well as in FTTx deployments involving narrow conduits and building entry points. While bend-insensitive fibers like G.657 allow tighter bends, correct routing, slack management, and controlled bend points remain essential. Additional mechanical stress and environmental factors further reinforce the need for conservative bend radius design to maintain long-term transmission stability.

Key Takeaway

Maintaining the correct fiber optic bend radius is fundamental to network reliability, as most fiber performance issues originate from installation practices rather than cable quality. By adhering to bend radius and tensile limits, using proper cable management systems, and validating installations through optical testing, network operators can significantly reduce attenuation, extend fiber lifespan, and ensure consistent high-speed data transmission across all deployment scenarios.

Conclusion

Understanding and controlling fiber optic bend radius is fundamental to building reliable fiber networks. From data centers to FTTx systems, proper bend radius management prevents signal loss, reduces maintenance costs, and ensures long-term stability. By following industry best practices and manufacturer guidelines, network designers and installers can maximize the performance of infrastructure.

Frequently Asked Questions

Q: What is the difference between bend radius and diameter?

A: Bend radius refers to the inside curve of a cable bend, whereas diameter is the full width of the bend circle (diameter = 2 × radius). Instruments like pulleys are often specified by diameter.

Q: Can bending fiber too tightly permanently damage the cable?

A: Yes — tight bends can cause microcracks or fractures in the glass fiber that may not show immediately but degrade performance or break the fiber entirely.

Q: Does bend radius matter for both single-mode and multi-mode fiber?

A: Yes — all fiber types have specified bend radius limits, and exceeding them can cause signal loss and performance issues. Always check manufacturer specs.

Q:What happens if I ignore bend radius guidelines?

A: Ignoring bend radius can void manufacturer warranty, cause signal attenuation, cable damage, and network outages.nce in fiber optic cable manufacturing.